Partners and Solutions

- YAUZA Line of Products – Burglar and Fire Alarm System

- ELAN Linear Heat Fire Detector

- Products of International Partners

LATEST FROM OUR BLOG

- Ervist Group of Companies in Partnership with NPO Spectron Aggressively Implements Import Substitution Program in Russian Security Industry

- Cost-Effective Russian Solution in Intrinsic Safety for Hazardous Environment

- Expert Schit (ИП 101 / 435-3-P) combined fire detector (gas/heat)

- Upgrade of ELAN Linear Heat Detector

ELAN Linear Heat Fire Detector

Competitive Highlights

- First Russian development of fire security system based on Distributed Temperature

Sensing (DTS) technology - Efficient and cost effective solution for quality monitoring of fire hazards – with its span over 8 km

is equal to 2,000 addressable fire detectors - Minimized maintenance services

- Accurate and precise fire detection, including its direction

- Utilizing passive fiber-optic cable that is operational in harsh environment – excessive moisture

dirt, dust, smoke, corrosion (including dust salt in marine surroundings); indoor and outdoor

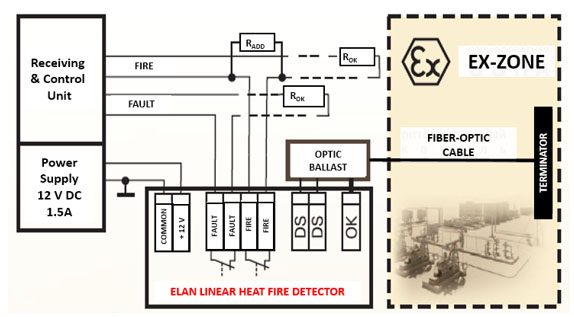

installation; resistant to electromagnetic and radioactive exposure - Manufactured for general purpose industrial and explosion-proof operations. Explosion-proof

grading (according to the Russian GOST R 52350.28-2007) for fiber-optic cable is

Mark [Ex op is T6 Ga] IIC or [Ex op is Ma]; while all equipment is located outside hazardous area - Simple system integration, scalability, and standard interface protocols, flexible customization to

existing security and fire protection systems - Does not require any communications infrastructure; no continuous control needed

- Uncomplicated installation - existing cable and wire routes, belt conveyors, storage space and

technical floor/subfloor can be used

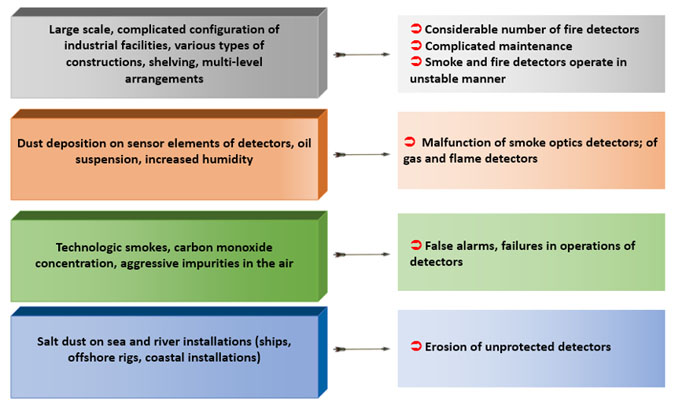

Modern production facilities utilize a huge variety of equipment – pressurized installations, lifting and transport machines, gas-consuming systems, and various power supply resources. All of them, in addition to the dangers inherent to a particular production (e.g., vapors in Oil and Gas), further contribute to the formation of hybrid air mixtures, which can lead to emergencies.

This affects the integrity and functionality of devices and fire alarm systems.

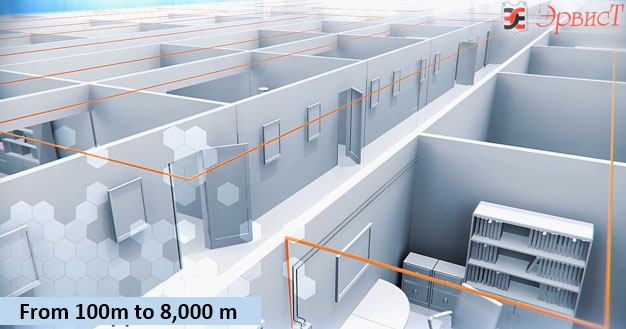

Based on DTS Technology, ELAN Linear Heat Detector is deployed for fire hazard protection of heated/unheated premises, large scale extended open air and underground sites included. ELAN pinpoints fire origination – accurate temperature change and precise location - than sends FIRE notice to control unit. Due to its non-electric character and utilization of fiber-optic cable ELAN can be used at Oil and Gas facilities, at chemical production plants (with aggressive environment), as well as at metallurgical production and energy-generating facilities.

ELAN locates fire origin within 4 meters and provides opportunity for addressable fire extinguishing

As compared to DTS systems, ELAN operates in virtual zones of 4 meters that are cut over the sensor cable length. Within each zone, over the 4 -meter interval integration of the temperature occurs. The 4-m length is established in accordance with the SP5 13130.2009 Russian Technical Regulations, which require this distance between two installed point detectors. The integration process allows populating the zone with virtual point thermal detectors. This allows accurate consideration of temperature distribution during thermal flare’s impact on the fiber optic cable. Detection accuracy is multiple to virtual zone length, i.e. to 4 meters.

In AUTOMATIC mode (data transmission) ELAN transmits data to the upper level, which may be a computer or Automatic Fire Suppression System (AFSS). Connectivity to the upper-level devices (computer or ASPS) is provided through USB output of ELAN. For devices that use RS485, RS232, interfaces is connected via a converter “USB – THAT DEVICE INTERFACE". ELAN communication protocol is open and compatible with most existing Reception Control Devices, easily connecting to majority of fire and security alarm systems.

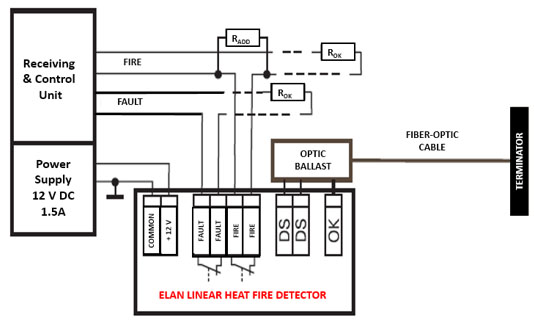

ELAN is deployed with Receiving & Control Units (RCU) that are operating with two loops. They are processing and registering three different loop stats: NORMAL, FIRE and FAULT.

Typical ELAN deployment with RCU

Typical ELAN deployment in hazardous environment with RCU

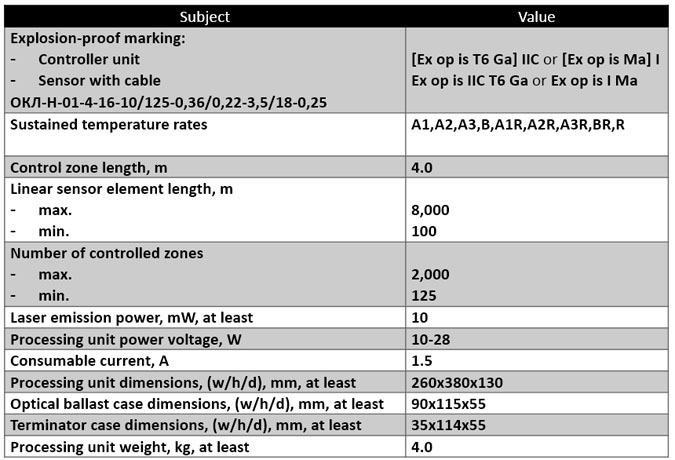

Technical Specifications of ELAN

Interested in more information?

Please, submit an inquiry to info@ervist.ru